The PV industry is currently experiencing a rapid phase of development, fueled by the global pursuit of carbon neutrality. With the continued rise in installations of distributed PV systems, the industry faces several critical challenges. These challenges include generating capacity losses due to module mismatch, potential safety risks arising from high DC voltage, disorganized distribution of multiple power plants, and low operation and maintenance efficiency, among others.

As such, Sungrow launched the SP600S smart power optimizer, a groundbreaking MLPE (Module Level Power Electronics) product enhancing solar system efficiency and safety. The SP600S is designed to increase generating capacity, boost rooftop installation capacity, and improve PV system safety, while enhancing installation and O&M efficiency. It sets the pace for product innovation and transformation in the industry, making every PV module more efficient and safer throughout its entire lifecycle.

Module-level independent optimization increases generating capacity by 30%

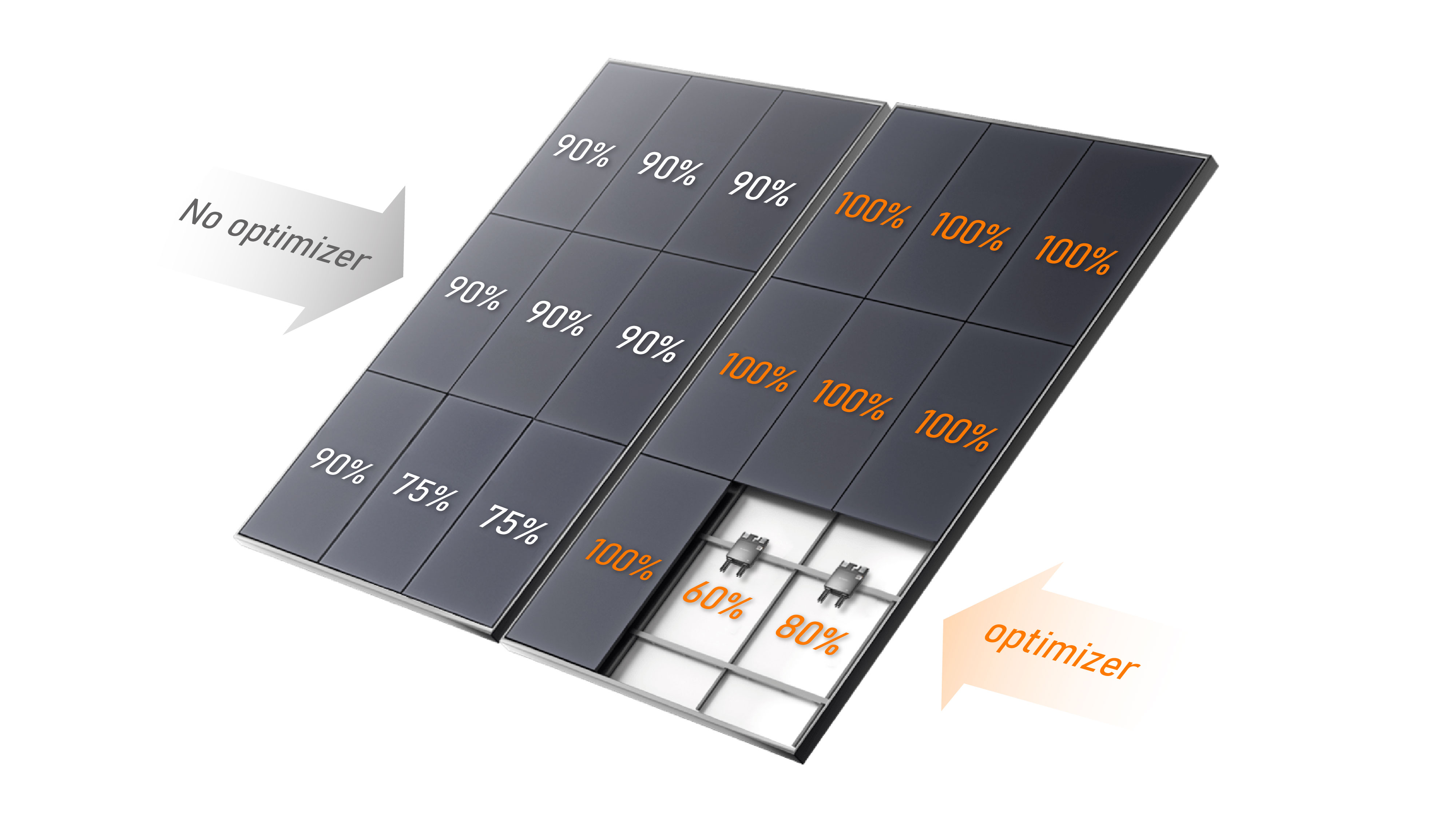

During the long-term operation of distributed PV systems, partial shading of modules by dust, tree shades and bird droppings as well as differences in module performance degradation. These factors can cause module mismatch, resulting in "barrel effect" throughout the entire PV string and ultimately decreasing the system’s generating capacity. Thanks to the innovative shadeproof smart control technology developed by Sungrow, the SP600S can separately optimize mismatched modules.

To cope with the ever-changing shading conditions, resulting from varying sunlight angles and orientations, Sungrow’s shadeproof control technology automatically detects the sun exposure status of the modules in real time. When a module is shaded, the SP600S optimizer automatically switches to the BUCK operating mode to optimize it separately, while the unshaded modules continue to operate as usual; when the shading is removed, the optimizer switches to the power-saving mode. This way, the SP600S minimizes system operating losses and ensures that the entire PV system is always in its optimal operating state, thus maximizing power output.

After installation, the SP600S increases the overall generating capacity by 4% to 30% (the exact performance depends on the actual operating conditions of the power plant).

Customizable design raises rooftop installation capacity by 20%

Due to the varying roof orientations, the design and installation capacity of PV systems are often limited, which can negatively impact the power generation income per roof. However, with the module-level optimization feature of the SP600S, this limitation can be overcome. The product offers customization for different types of rooftops, supporting single-string multi-orientation installation. It can accommodate up to 30 modules per string to achieve the optimal installation capacity and it supports mixed installation of strings with different lengths and modules with different power ratings, making the system design process more flexible. The SP600S can boost rooftop installation capacity by 20% to 30% on average, significantly improving the utilization rate of rooftop resources.

Module-level shutdown provides all-round protection covering the entire lifecycle of PV systems

The SP600S allows module-level rapid shutdown, which guarantees a safe DC voltage of the PV power plant throughout its lifespan. During installation, the optimizer keeps an output voltage of 1V in an inactive state, ensuring a safe low-voltage installation process. During routine maintenance, the module voltage can be lowered to 1V by disconnecting the AC power supply or triggering an external switch, ensuring safety during maintenance. In case of an emergency, such as a fire, the optimizer automatically shuts down relevant modules within 20 seconds, which is 10 seconds faster than the NEC2017/2020 requirement. This reduces the string voltage to below 30V, ensuring the safety of firefighters and minimizing or avoiding losses of the project owner.

Highly efficient MBS O&M makes diagnosis faster, more accurate and with reduced power losses

After installation of the SP600S, users can obtain a module twin layout diagram on the iSolarCloud app by using the one-click OCR scan. This diagram helps users to quickly identify "sub-healthy" and faulty modules. The status of each module is displayed in real-time through color-coding, enabling efficient MBS (Module Based Service) operation and maintenance. For the status monitoring purpose, dark blue represents modules in the optimal running state, light blue indicates modules in the "sub-healthy" state, and red denotes modules in the faulty state.

For problematic modules, the SP600S initiates module-level IV scanning to automatically diagnose the faults, identify the causes, and provide troubleshooting suggestions, thereby enhancing O&M efficiency. The SP600S can accurately identify eight types of faults. During diagnosis, healthy modules operate normally and generate electricity without being affected. The module-level IV scan feature of the SP600S reduces system power losses by 8% to 30% compared with the traditional string-level IV scan.

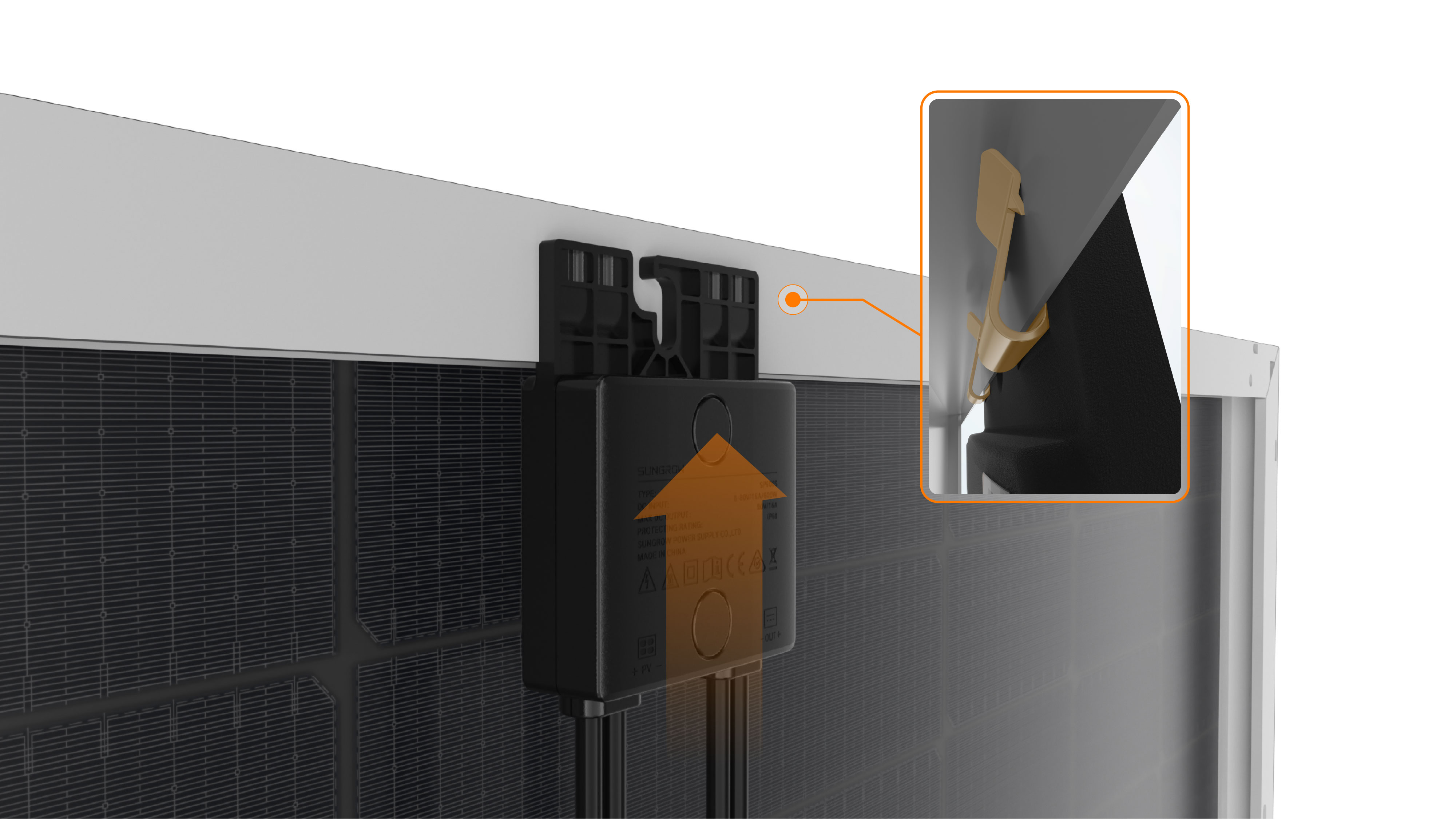

"Tool-free" installation leads to 40% efficiency boost

Installing the SP600S is easy and can be done using regular bolts and fasteners, or with a mounting buckle that requires no additional tools. The patented buckle design is capable of withstanding forces up of 16 times its weight, without requiring any auxiliary tools. Just buckle it - that’s it! Installation only takes 35 seconds. This hassle-free design improves installation efficiency by 40%.

* The accuracy of the data presented in this article is contingent upon the actual test conditions.